I wasn’t really able to complete all my goals this week with regards to making an algorithmic design for the laser cutter but I do think I now have a solid understanding of how I will complete it eventually. The concept I’m working towards is essentially a type of grip for the back of a smartphone.

The inspiration for this product comes from a device I already own that fixes a hard plastic ring to the back of the phone.

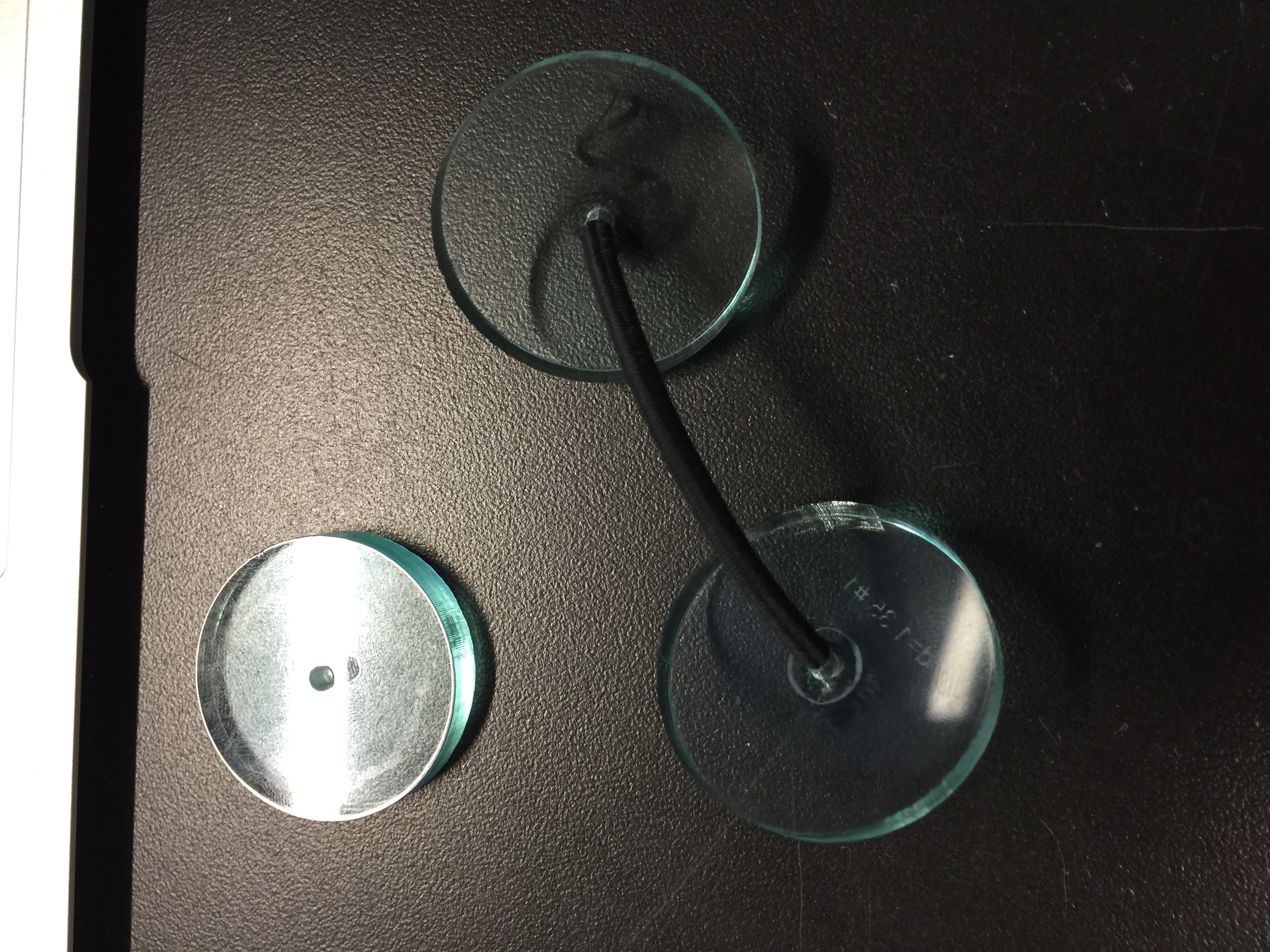

In my first attempt last week I developed a basic design for my phone grip out of two disks with a hole in the center connected by some elastic cord.

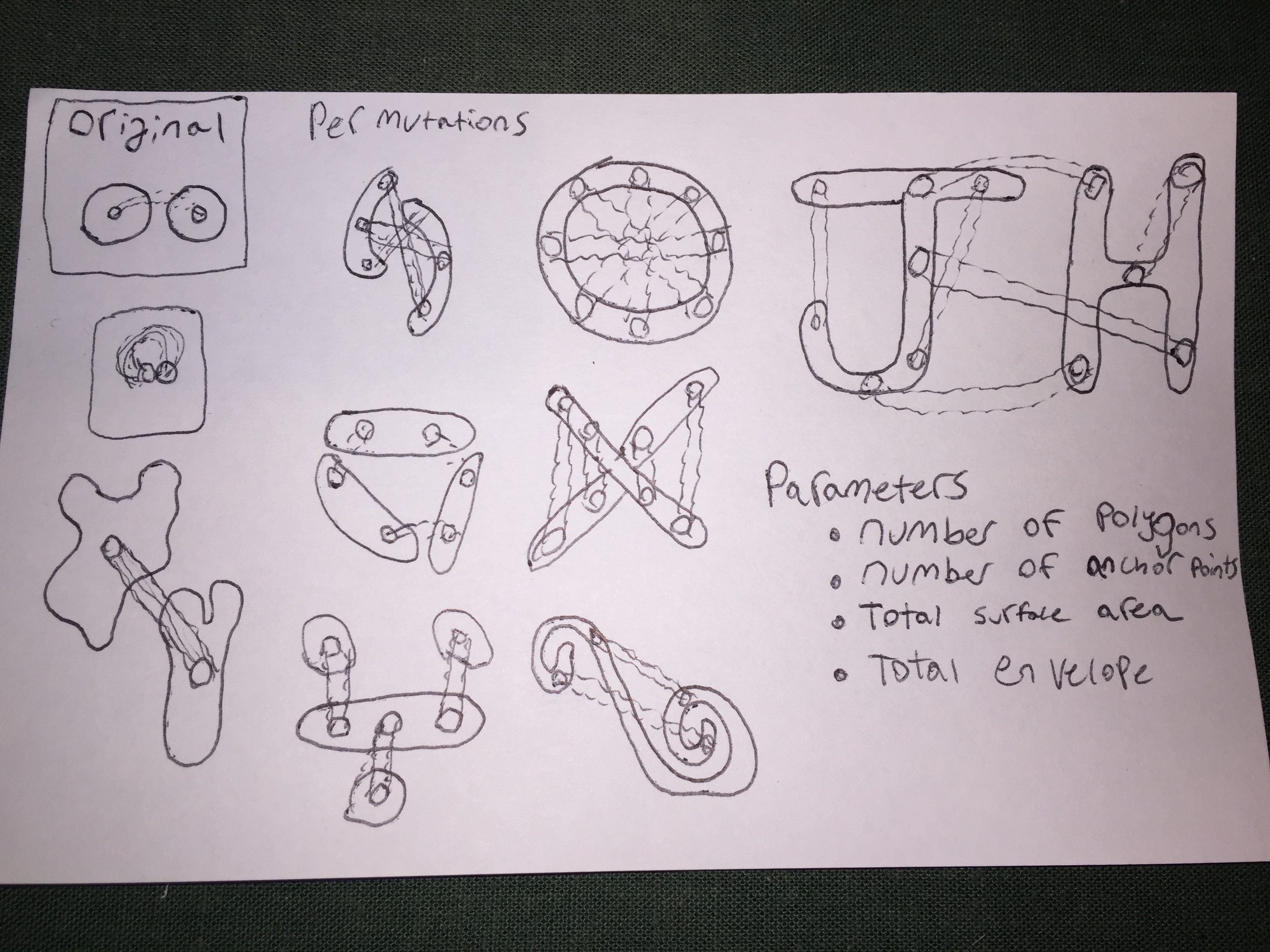

It occurred to me that the base for these bungee cords could be almost any shape as long as they maintain some minimum surface area with the phone (to ensure that the adhesive will be able to resist any forces pulling the bungee cords away from the phone). So my goal for this week was to find or develop some software that will allow me to rapidly make permutations of these bungee bases without radically altering the surface area. This requires an equation know as the shoelace formula that takes all there vertices of a shape and calculates the area. I had a hard time with processing vectors since most of my background was in p5 but I think with more time I could successfully implement it. Lacking a sketch to generate these shapes I tried to imagine a few varieties:

In my attempts in Processing I came up with a few bloby objects that could work but this is far from what I’d like the final software to look like.